Original blog by YUFA Polymer Products Co., Ltd.

Production Site: Shenzhen, China

info@yufapolymer.com | �� www.yufapolymer.com.

1. Why Anti-Static Foam Matters in Electronics Packaging

Electrostatic discharge (ESD) remains one of the silent killers in the electronics industry. A single spark invisible to the human eye can permanently damage sensitive components such as PCBAs, IC chips, or optical modules. Traditional packaging materials like regular foam or plastic do not provide electrostatic protection, leading to risks of latent failures or high scrap rates.

Anti-static EVA foam (resistance range: 10⁵–10⁹ Ω) provides a safe balance: it prevents static build-up, gradually dissipates charges, and ensures that sensitive electronics are not exposed to sudden discharges.

�� 2. Typical Applications of Anti-Static EVA Foam

Anti-static EVA foam is widely used across electronics manufacturing and export packaging:

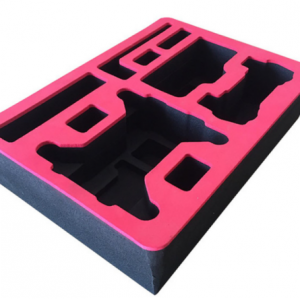

· Electronics packaging liners – Protect PCBAs, IC chips, sensors, and light modules during storage and shipment.

· ESD-safe cushioning materials – Used in SMT workshops, tool fixtures, and returnable boxes.

· Consumer electronics shipping – Smartphones, tablets, wearables, and accessories.

· Precision instruments – Packaging for measurement devices, optics, and small diagnostic equipment..

⚙️ 3. Customer Pain Points Solved

When manufacturers choose anti-static EVA foam, they are addressing real operational challenges:

· Reduce ESD risk – Prevents latent damage during storage, handling, and export shipping.

· Controlled static dissipation – Unlike conductive foam, it avoids direct short-circuits on exposed contacts.

· Reliable cushioning – Soft yet durable material protects against vibration and impact.

· Cost-effective solution – Provides ESD protection at a lower price point compared to conductive foams.

�� 4. Technical Highlights

· Hardness: 38 Shore C (customizable)

· Color: Black (standard), other colors optional

· Density: Customizable per project

· Surface resistance: 10⁵–10⁹ Ω (permanent anti-static)

· Processing options: Die-cutting, CNC profiling, lamination with ESD films, adhesive backing available

�� 5. Industry Value & Market Trend

With the rise of AI chips, 5G communication modules, and smart devices, the demand for reliable anti-static packaging materials is increasing globally. Anti-static EVA foam strikes the right balance between safety, cost, and flexibility, making it the preferred choice for:

· Electronics OEMs & ODMs

· Export packaging suppliers

· Consumer electronics brands

· Third-party logistics companies handling sensitive components

�� 6. Final Thought

Not every application requires conductive foam. For the majority of electronics manufacturers, anti-static EVA foam provides the optimal solution—strong cushioning, safe static dissipation, and cost efficiency. It’s the material that bridges product safety and operational value.

�� Contact us to customize your ESD packaging solution today:

�� info@yufapolymer.com

�� www.yufapolymer.com